Automatic lubricators offer many advantages including worker safety, time and cost savings, increased lifespan of machines, and efficiency which translates in reduced time manually lubricating pins, bushings, gears and or other components.

What Is An Automatic Grease System? An automatic grease system, also commonly referred to as a centralized lubrication system, is a system that delivers precisely controlled quantities of grease to one or multiple lubrication points on a machine while it in operation.

Automatic lubricators offer many advantages including worker safety, time and cost savings, increased lifespan of machines, and efficiency which translates in reduced time manually lubricating pins, bushings, gears and or other components.

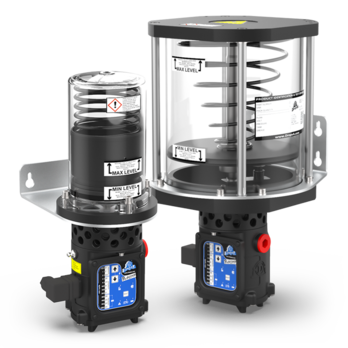

Automatic grease systems come in a range of sizes and designs to accommodate your vehicles or equipment. Whether you’re using a range of die presses or a fleet of trucks, automatic grease lubrication systems are available in these basic types:

A single-line system is the most compact and affordable. These are best for use on vehicles or light equipment that can’t afford excess space. Dual and multi-line systems are designed for industrial purposes. Grease multiple points at once through a single, efficient control station.

A progressive system features specialized controls to adjust the amount of grease applied to each grease point. This unique option is ideal for minimizing excess grease use and for efficiently lubricating complex equipment.

Each type of system comes in a range of sizes and designs. Some of our automatic lubrication systems use an extensive network of sensors and lubrication points to accurately apply grease to multiple areas. Other systems are basic, compact and affordable. These small-scale lubricators allow you to adjust the amount but only deliver grease to a single point.

Automatic grease systems reduce your maintenance routine by eliminating the need to manually lubricate various points. Hassle-free maintenance allows your team to spend more time tackling emergency issues and less time greasing gears, pins, bushings and other components. Auto lube systems also ensure accurate grease application. Some components require a fine-tuned amount of lubrication and excess grease can damage equipment or waste materials. Dial-in your lubrication needs with near-dry machining or an air/oil lubrication system.

Finally, automatic lubrication systems are highly customizable. If you discover that you’re applying too much or too little lubrication, simply adjust the centralized control station. Some systems are equipped with sensors that help you determine the exact amount of grease at each point. Others are more basic and require you to visually inspect each point.

Auto grease systems are used in a wide variety of applications. It is important to consider whether a single-line, multi-line or progressive system will best suit your needs. Some common applications for these systems include:

Heavy trucks require periodic greasing for continual maintenance. Install one of our automatic grease systems onto your semi truck, cement truck, fire truck or waste hauler for efficient greasing of all the key components. Here are some benefits of an auto lube system for the trucking industry:

Browse our selection of pumps and controllers, or work with our customer service team to find the ideal solution for your fleet. Whether you’re an owner-operator with a single truck or have an entire fleet of construction and transportation vehicles, an auto lube system is an affordable alternative to manual greasing.

Construction vehicles need the same level of routine maintenance and lubrication to perform their duties. Automatic grease systems replace time-consuming and hazardous manual lubrication on excavators, dump trucks and other construction equipment. Consider these reasons why you should avoid manual excavator lubrication:

Streamlining excavation lubrication keeps your equipment moving for longer, saving you hours a week of productivity. Auto lube systems also promote a safer workplace and can reduce the risk of jobsite injuries.

Automatic grease lubricators improve machine reliability through a series of components. Components can vary depending on the type of system you are using. Here are a few of the key components auto lube systems typically include:

The entire system is powered by an electric, hydraulic, pneumatic or mechanical pump. Automatic grease systems use a range of pump sizes and specifications depending on the number of fittings and lines, as well as the type of lubricant. Automatic grease lubrication systems used in trucks and excavators use multiple injectors and a small pump that can be mounted directly on the equipment. Larger industrial machinery may use a larger, stationary pump.

Greasing isn’t a continuous lubrication process, so you need a controller to set the frequency and amount of application. State-of-the-art controllers, like the VIP5 Controller, offer pulse, cycle and flow features. A simple menu and easy-to-read screen allow drivers to operate automatic grease systems from inside the cab.

Various sensors and monitoring devices prevent automatic grease systems from over-supplying grease points or leaking grease onto other areas of your equipment. Discuss the best monitoring system for your particular application with our customer service team to help monitor your system.

In addition to pumps, controllers and monitoring devices, automatic grease systems have a range of valves, lines, sprayers and injectors. These all depend on the type of system you choose.

Single-line lubrication uses a controller and connects the pump to a single sprayer or injector. Most equipment has more than one grease point, so this style of system is rare with this lubrication process. Dual-line lubrication is more common, but still is only capable of applying lubrication to two areas.

Multi-line and progressive grease systems are the most commonly used in trucking, construction and other industries. The primary difference is that multi-line systems may not be able to adjust the amount of grease sent to specific applicators, while a progressive system uses a series of valves to adjust the flow rate to every area of your equipment.

Compare our automatic grease systems today to see why DropsA North America is a leader in centralized lubrication. Shop for automatic lubricators easily through our online store. Feel free to ask our customer service team about the best automatic grease lubrication system for your needs or explore our catalog to find innovative solutions for your company. Don’t settle with manual lubrication, but invest in an affordable, efficient lubrication system from DropsA North America today.

Explore our wide selection of cutting-edge lubrication systems designed to keep your machinery running smoothly.