We offer a variety of automatic grease lubrication systems and solutions including dual line systems, progressive divider systems, grease pumps and more.

Our team specializes in the design, engineering and installation of industrial lubrication systems. We also stock all the parts and components the systems require.

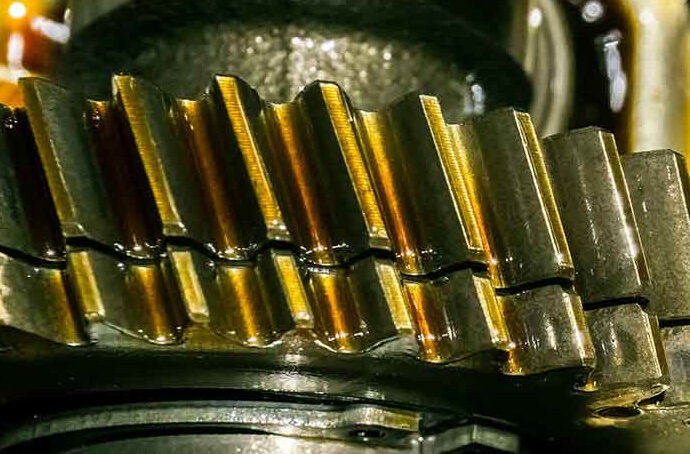

Recirculating oil systems keep a continuous flow of oil to ensure exact quality, quantity and temperature while also reducing oil waste.

Our air oil lubrication systems are engineered to achieve maximum customization for improved performance and decreased maintenance costs.

DropsA is an industry leading provider of minimum quantity lubrication systems. Our modular systems can be customized to suit your machining needs.