Advantages

Industrial lubricating oils can be costly.

Whether your machinery operates continuously or you need a lubrication solution for your specialty heavy equipment, choose an MQL system for near-dry performance. High-speed cutting, die presses, heavy equipment and automotive manufacturing are just a few industries that need MQL systems for efficient operation.

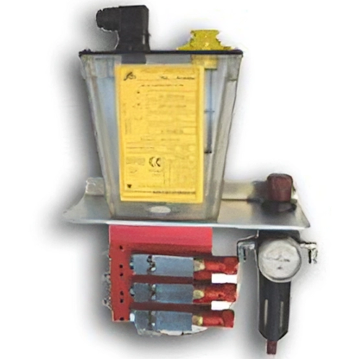

A minimum quantity lubrication centralized system uses air and oil to deliver calibrated amounts of oil at designated areas. The benefits of MQL machining are exponential as you continue to save oil and keep your machinery running with the perfect amount of lubrication.

Key Features

Before discussing your specific air and oil centralized lubrication system options, consider the advantages of using this type of system. Not only will our quality pumps last longer, but they’ll also protect your equipment with accurate, adjustable lubrication to increase the lifespan of your critical components. Here are some key features that help you understand the difference a DropsA lubrication system can make in your industry:

Air-Powered Precision

An air and oil system achieves MQL results by using pressurized air to deliver the smallest amount of oil needed to the intended area.

Improved Industrial Performance

Maximize the output of your presses, machining tools and heavy equipment by keeping essential components adequately lubricated.

Adjustable Specifications

Not only do we provide a wide range of air and oil lubrication systems, but you can also accurately adjust the amount of oil, frequency of impulses and other key specifications as your pump operates.

Guaranteed To Deliver

At DropsA, we design products that are guaranteed to deliver the results you need and able to withstand the routine wear and tear of your industry.

IoT

Monitor maintenance schedules, access replacement part information and more with our innovative internet of things technology.