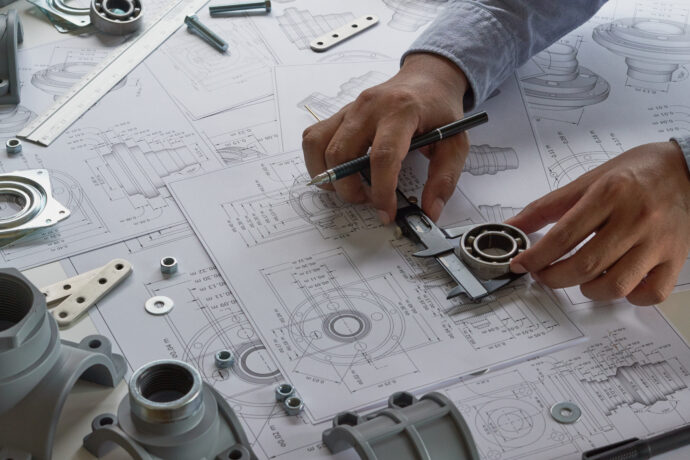

DropsA North America’s Sales Engineers, Engineering department, and Inside Sales team have decades of experience in lubrication system design, engineering, implementation, and knowledge across numerous industries and a vast array of applications.

DropsA North America has an Engineering staff / department on hand to develop and generate custom lubrication and controls solutions for applications that require a lubrication system beyond the norm.

DropsA North America offers technical support via phone, virtual chat support, and in-person troubleshooting to offer customers the highest level of support when needed.