Common Applications

Automatic lubrication systems are used by manufacturers in many industries, including manufacturing, demolition, food processing plants, and waste processing. These types of systems are commonly used in chain drive machines.

Any equipment that requires frequent application of oil can benefit from one of our innovative systems. Common industries include construction, automation, machine tools, wind energy, food and beverage and mining.

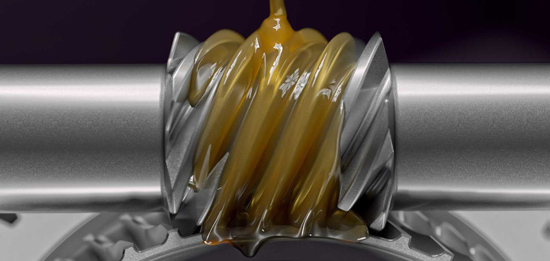

Many of our systems are designed to offer continuous lubrication of moving gears. Other options distribute a precise amount of cutting oil to an exact point of contact, which is useful for CNC machining and other cutting, drilling or manufacturing processes.

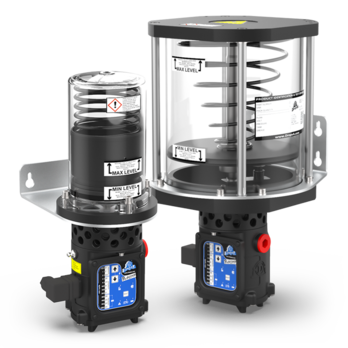

You don’t need to operate a sprawling manufacturing facility to take advantage of our systems. A centralized lubricator can be used in agricultural machinery, off-road machines or small food and beverage equipment. Small businesses, hobby farms or personal equipment can all benefit from one of our efficient lubricators.

Our solutions are highly modular, meaning that you can select the type of system that works for you and make it fit into any type of plant. This also simplified maintenance because sections can be taken offline separately as needed. Our customer service team will help you to determine the right selection and combination of products for your needs.