Lubrication manifolds, or pneumatic manifold blocks, come in a variety of sizes to adapt to all space dimensions. They feature separate valve blocks that deliver specific amounts of lubrication to multiple points. They are also designed to utilize tubing so that more inaccessible areas can receive adequate lubrication.

If you have a centralized lubrication system in your facility, you’ll need a pneumatic manifold.

Types of Lubrication Manifolds

Manifolds can have a variety of port sizes, pressure ratings, flow rates, station numbers, and functions. They may also be brand-specific, which limits the use of valves to brand-specific valves. Other types of manifolds comply with standardized mounting patterns so that they can be combined with valves not manufactured by certain brands.

The classic way to categorize lubrication manifold types is by the system they’re designed for:

Single-Line

These manifolds are designed for single-line systems, where one main line feeds lubricant to the manifold and distributes it to multiple lubrication points.

Dual-Line

These are designed to handle two main feed lines. They alternate between the two lines to supply lubricant and are often used in heavy-duty applications where high-volume lubricant is needed at multiple points.

Progressive

Progressive manifolds are used in progressive systems. Each outlet in the manifold receives lubricant only when the previous outlet has received the correct amount.

Injector-Based

Injector-based manifolds use injectors rather than valves at each outlet to deliver lubricant. Each injector can be individually adjusted.

Modular

Modular manifolds are extremely flexible and can be customized based on the specific lubrication needs of different machinery. They can even be expanded and reconfigured to adapt to changing operational requirements.

Selecting the Right Type of Lubrication Manifold

When selecting a manifold, you need to consider the application of your entire lubrication system, as well as the type of system that you have. Some elements you’ll want to consider are:

- Material: This can help prevent corrosion and other damage to your equipment.

- The Size of Your Ports: Consider the thread size and speed installation.

- Number of Stations: You will also need to consider how many lines that you need to connect to your distribution point.

- Operating Pressure: Make sure that the operating pressure of your selected manifold can withstand the operating pressures of your total system.

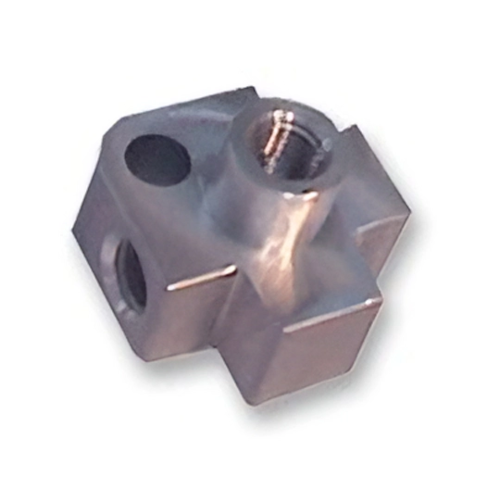

Our Available Models

Below are the manifold blocks that we manufacture and their features. Each block is designed to be used with any of our automatic systems. We can also customize each manifold to meet the needs of your existing system.

01 Manifolds

- Junctions Have Two Fixing Holes

- Uses Junction Meter Units Type D21 and DDJ

- Designed for 4 Millimeter (5/32-Inch) Tubing Only

- Seating Is 54 Degrees

- Holes are Interconnected

- Threads are 5/16-Inch to 24 NF (National Fine)

- Can Feature Up to 14 Outlets

33V Manifolds

- Available as a Single Row or Double Row

- 33V With M10 Valves Is Compatible With an M10 Manifold

- ⅛ BSP (British Standard Pipe) Thread

- Up to 16 Outlets

Type W Manifolds

- Backward Compatibility for an Existing System

- Designed for Valves 0.03 to 0.16 Cubic Centimeters Per Stroke

- ⅛ BSP (British Standard Pipe) Thread

- Up to 8 Outlets

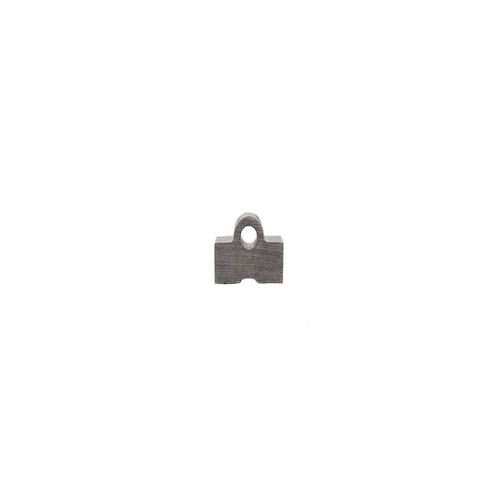

Injector

- Features Up to 8 Outlets

- One Row

- Compatible With Most Injector-Based Lubrication Systems

Orifice S Manifold

- Designed for Cylindrical Metering Units

- Available in Multiple Styles (Elbow, 90 Degrees, Straight)

- 2 to 5 Outlets Available

Orifice Single Row

- Designed for Cylindrical Metering Units

- One Row

- Features 4 to 12 Outlets

Find the Right Lubrication Manifold Today

DropsA is a global leader in centralized lubrication systems. When you turn to us for custom lubrication systems and components, like lubrication manifolds, you can expect rapid response times, fast shipping, and exceptional customer support.

To learn more about our solutions, please visit our catalog. If you have questions or need help selecting the right model for your system, don’t hesitate to reach out to us.