What is a Single-Line Progressive System?

This single line lubrication system uses a single pump and line to push lubricant through to each individual valve and injector. The signal that starts the event turns the pump on and forces the liquid to each valve. These valves aren’t typically adjustable and pump out a predetermined amount of oil or other lubricant.

While this efficient system is one of the most basic. In the event of a leak or blockage in a single section of the line, the remaining valves won’t receive enough continuing pressure to properly lubricate your equipment.

What is a Dual-Line Parallel System?

For even more specialized injection, review dual-line auto lube systems. These powerful systems use two main lines to increase the available lubricant and number of injectors substantially. A dual-line parallel system, with the correct pump and injectors, can easily service an entire production facility with hundreds of individual injectors all dispensing a precise amount of oil.

One main supply line is used to pressurize the system, while the other is used as a vent line. The main lines are interchangeable and are typically cycled to prevent one line from always being used as the pressurized one.

What is a Multi-Port System?

These auto lube systems use innovative cams in the drive motor to activate injectors. This allows you to control which injectors are operating during which cycle, so the entire system doesn’t have to be on the same lubrication schedule.

What are the Differences Between Manual and Automatic Lubrication?

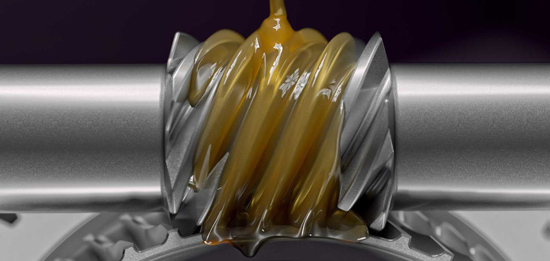

Lubrication is essential for keeping your cutting tools operating efficiently and preventing moving parts from experiencing excessive friction. Lubricating moving parts typically takes time and requires a maintenance technician to physically move around the machine to access every grease point. Compare automatic vs manual lubrication to see how you can benefit from the ease of an automatic system.

Lubrication is essential for keeping your cutting tools operating efficiently and preventing moving parts from experiencing excessive friction. Lubricating moving parts typically takes time and requires a maintenance technician to physically move around the machine to access every grease point. Compare automatic vs manual lubrication to see how you can benefit from the ease of an automatic system.

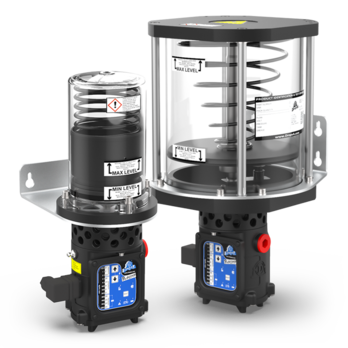

Automatic grease lubricators allow you to control the amount of grease and lubrication applied from the comfort of a safe control panel. Lubrication is also applied while the equipment is in operation which saves downtime. Some systems also include sensors to help you monitor the amount of lubrication on a point to prevent wasted lubricant.

Most manually applied grease maintenance tasks are inefficient. A manual application typically uses more grease, so it isn’t a cost-effective solution. It also takes your maintenance team a considerable amount of time to apply to each of your facility’s grease points. Consider using a minimum-quantity system or an air/oil lubrication system to keep your equipment operating efficiently with minimum wasted grease.

Manual greasing can also prevent your equipment from receiving the lubrication it needs. If your maintenance team doesn’t keep a consistent schedule, your costly equipment may be damaged due to a lack of grease. Don’t let this minor maintenance task cause major damage to your equipment, but keep your machinery gliding along with accurate, controlled lubrication.

Where can I Find Custom Lubrication Solutions?

Compare these four basic types and our unique lube systems to find the ideal solution for your industry and your equipment. Whether you need to grease axles or you need near-dry lubricant for precision components, a DropsA North America system reduces the time and cost of your lubrication process.

At DropsA North America, our auto lube systems cover all of these basic categories as well as custom ones to match your facility. Discuss your lubrication needs with our team to determine the best course of action for your situation.

We provide standard and custom products that fit all the common types of automatic lubrication systems. In addition to offering full-service feeders, we have an extensive inventory of controls, pumps, feeders, injectors and auxiliary equipment to keep your existing system maintained and ready for production. Our team not only manufactures these systems, but also engineers custom solutions and installs new systems for full-service support.